Factory Price Peanut Butter Machine

- Inombolo yoMfanekiso:

- JPF-GJL0012

- Indawo yemvelaphi:

- Shanghai, China

- I-Voltage:

- 380V/220V

- Isiqinisekiso:

- CE/ISO9001

- Iwaranti:

- Iinyanga ezili-12

- Inkonzo yasemva kokuthengisa ebonelelweyo:

- Iinjineli ezifumanekayo zokunikezela ngenkonzo koomatshini phesheya

- Umqathango:

- Entsha

- Uhlobo:

- umatshini wokwenza ibhotolo yamandongomane

- Izinto:

- iStainless Steel 304&316

- Ukusetyenziswa:

- Ukusetyenziswa kwemizi-mveliso

- Umthamo:

- 10-60 t/h

- Umba:

- ishishini iziqhamo imifuno puree machine

- Umbala:

- isilivere okanye yenziwe ngokwezifiso

- Uphawu:

- Jika iProjekthi engundoqo

- Umsebenzi:

- Imisebenzi emininzi

- Ukubonelela ngeSakhono:

- 10 Iseti/IiSeti nganye yeNyanga yomatshini wokwenza ibhotolo yamandongomane

- Iinkcukacha zokuPakisha

- Iphakheji ye-1.Stable yokhuni ikhusela umatshini kwisiteleka kunye nomonakalo.Ifilimu yeplastiki ye-2.Inxeba igcina umatshini ngaphandle komswakama kunye ne-corrosion.3.I-Fumigation-free package inceda i-smooth customs clearance.4.Umatshini omkhulu wesayizi uya kulungiswa kwisitya ngaphandle kwephakheji.

- Izibuko

- eShanghai

- Ixesha lokukhokhela:

- Iintsuku ezingama-30

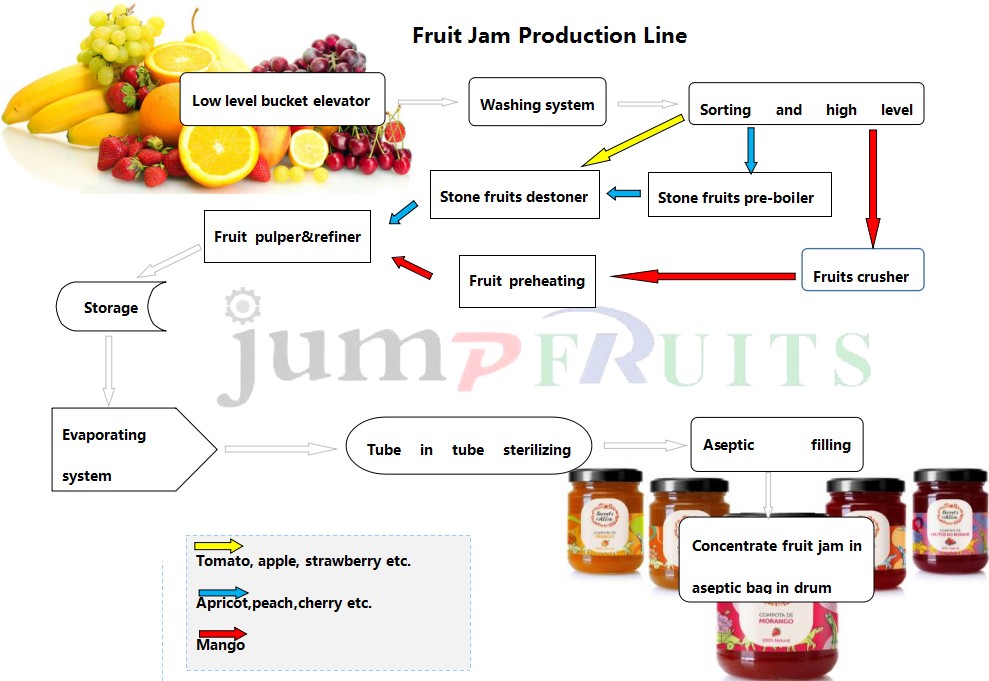

2.Ukwakheka komgca wonke:

A: inkqubo yokukhuthaza iziqhamo zokuqala, inkqubo yokucoca, inkqubo yokuhlela, inkqubo yokutyumza, inkqubo yokufudumeza inzala yangaphambili, inkqubo ye-pulping, inkqubo yoxinaniso yevacuum, inkqubo yokuvala inzalo, inkqubo yokuzalisa ibhegi ye-aseptic.

B: impompo → igubu lokudibanisa → i-homogenization → deaerating → umatshini wokuvala inzala → umatshini wokuhlamba → umatshini wokuzalisa → umatshini wokupakisha → umatshini wokutshiza wetonela → isomisi → ikhowudi → ibhokisi

Izinto zethu eziluncedo:

1.Turnkey isisombululo.Akukho mfuneko yakukhathazeka ukuba unolwazi oluncinci malunga nendlela yokwenza isityalo kwilizwe lakho. Asinikezeli kuphela izixhobo kuwe, kodwa sinikezela ngeenkonzo zokumisa enye,ukusuka kuyilo lwakho lwesitora (amanzi, umbane, abasebenzi), uqeqesho lwabasebenzi, ukufakelwa koomatshini kunye nokulungiswa kweempazamo, inkonzo yexesha elide emva kokuthengisa njl.njl.

Iminyaka eyi-2.15 yamava okuthunyelwa ngaphandle, lula ukuthutha imithwalo emnyango wakho

I-3.inkonzo eyenziwe ngokwezifiso, siya kuzama konke okusemandleni ethu ukuhlangabezana neemfuno zakho.

4.Isiqinisekiso somgangatho: iinyanga ze-12.Emva koko, iinjineli zikwafumaneka ngeendleko zakho zokuhamba kunye neendawo ezisecaleni.Sibonelela ngenkonzo yobomi emva kokuthengisa.

Iingenelo eziphambili zomgca wenkqubo yethu:

1. Isantya esiphezulu sokuvelisa esiphunyezwe yinkqubo yentloko esandul 'ukuyilwa (intloko enye okanye iintloko zamawele ezikhoyo), ukuthembeka okuphuculweyo ukusuka kwi-PLC elawulwa ngokupheleleyo imo yokusebenza yokuxilonga.

2. Ukuguquguquka okukhulu ngokuhlangana nemigangatho eyahlukeneyo yokupakisha ngeemveliso ezahlukeneyo.

I-3 ilungelelanisa kakuhle kunye netyhubhu kwi-tube sterilizer, ukuba kukho ukungasebenzi kakuhle kunye ne-filler, imveliso iya kuba yi-automatic flow back kwi-tank ye-buffer phambi kwe-UHT sterilizer.

4. Ukusetyenziswa kwengxowa engenanto etywiniweyo etywiniweyo iqinisekisa ukuba isingxobo siya kuhlala sinyumba phambi kokuba sigcwaliswe.

5. Uxinzelelo oluphezulu lwe-steam saturated steam lusetyenziselwa inzala yokulungelelaniswa, i-cap kunye nenxalenye eveziweyo ye-filler ngaphambi komjikelezo ngamnye wokuzalisa.AKUKHO iikhemikhali ezifunekayo.

6. Ukutywinwa kwe-valve yokuzalisa ngaphakathi kwendawo yokufakela igcina imveliso kude ngokupheleleyo kwindawo yokutywinwa kwephakheji.

7. Ukutywinwa kokushisa kwe-hermetic ye-fitment kunika ukuvalwa okucacileyo kwe-tamper kunye nomqobo ophezulu we-oksijeni.

8. Uyilo lwe-aseptic lulonke lwe-filler luvumela ukungaphazanyiswa.Ukusebenza kulo lonke ixesha letumato / leziqhamo, ukwandisa ukusebenza kakuhle kwesityalo sakho

9. I-CIP kunye ne-SIP ekhoyo kunye netyhubhu kwi-tube sterilizer

Inkonzo yokuthengisa kwangaphambili

* Ukubuza kunye nenkxaso yokubonisana.

* Inkxaso yovavanyo lwesampula.

* Jonga iFactory yethu.

Emva koThengiso lweNkonzo

* Ukuqeqesha indlela yokufaka umatshini, ukuqeqesha indlela yokusebenzisa umatshini.

* Iinjineli ezifumanekayo zokunikela inkonzo koomatshini phesheya.

Iinkcukacha zokuPakisha: ukupakisha okusemgangathweni okuthunyelwa ngaphandle

Ukuhanjiswa kweNkcukacha: phakathi kweentsuku ezingama-50 okanye isicelo somthengi ngamnye

iibhotile zesiselo

91.8%Izinga leempendulo